Abstract

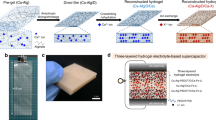

Two-dimensional (2D) ionogel membranes have emerged as a promising class of materials for broad applications in flexible electronics, smart robotics and artificial intelligence. However, the rapid, reliable and reproducible fabrication of ionogel membranes remains challenging due to difficult-to-control molecular behaviour. To overcome this challenge, we propose a ‘dip and peel’ strategy to exfoliate 2D ionogel membranes from a biomacromolecular gelatum (for example, a cellulose ionogel colloid) by controlling the solvent-induced supramolecular self-assembly. This strategy enables the simple and rapid fabrication of ionogel membranes with tunable shapes, controllable thicknesses, high ionic conductivity up to 14.1 mS cm−1, good stretchability exceeding 130% and excellent tandem duplication over 700 times. We further extend this strategy to fabricate different ionogel membranes from various biomacromolecules, including silk fibroin, chitosan and guar gum. Our results shed light on exploration of fundamental macromolecular interactions and provide an effective approach to prepare 2D biomacromolecular ionogel membranes with advanced functionalities.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are available within the paper and its Supplementary Information.

References

Pochan, D. & Scherman, O. Introduction: molecular self-assembly. Chem. Rev. 121, 13699–13700 (2021).

Johnson, E. K., Adams, D. J. & Cameron, P. J. Directed self-assembly of dipeptides to form utrathin hydrogel membranes. J. Am. Chem. Soc. 132, 5130–5136 (2010).

Cha, G. D. & Kim, D.-H. Toughness and elasticity from phase separation. Nat. Mater. 21, 266–268 (2022).

Chen, S., Costil, R., Leung, F. K.-C. & Feringa, B. L. Self-assembly of photoresponsive molecular amphiphiles in aqueous media. Angew. Chem. Int. Ed. 60, 11604–11627 (2021).

Hua, M. et al. Strong tough hydrogels via the synergy of freeze-casting and salting out. Nature 590, 594–599 (2021).

Levin, A. et al. Biomimetic peptide self-assembly for functional materials. Nat. Rev. Chem. 4, 615–634 (2020).

Zhao, X. et al. Soft materials by design: unconventional polymer networks give extreme properties. Chem. Rev. 121, 4309–4372 (2021).

Wang, J., Emmerich, L., Wu, J., Vana, P. & Zhang, K. Hydroplastic polymers as eco-friendly hydrosetting plastics. Nat. Sustain. 4, 877–883 (2021).

Zhang, B. et al. Dense hydrogen-bonding network boosts ionic conductive hydrogels with extremely high toughness, rapid self-recovery, and autonomous adhesion for human-motion detection. Research 2021, 9761625 (2021).

Zhao, D. et al. Cellulose-based flexible functional materials for emerging intelligent electronics. Adv. Mater. 33, 2000619 (2021).

Jiang, K. et al. Mechanical cleavage of non-van der Waals structures towards two-dimensional crystals. Nat. Synth. 2, 58–66 (2023).

Evans, A. A., Cheung, E., Nyberg, K. D. & Rowat, A. C. Wrinkling of milk skin is mediated by evaporation. Soft Matter 13, 1056–1062 (2017).

Simoncelli, S., Li, Y., Cortés, E. & Maier, S. A. Nanoscale control of molecular self-assembly induced by plasmonic hot-electron dynamics. ACS Nano 12, 2184–2192 (2018).

Qian, X. et al. Artificial phototropism for omnidirectional tracking and harvesting of light. Nat. Nanotech. 14, 1048–1055 (2019).

Wang, M. et al. Tough and stretchable ionogels by in situ phase separation. Nat. Mater. 21, 359–365 (2022).

Jiang, G. et al. A scalable bacterial cellulose ionogel for multisensory electronic skin. Research 2022, 9814767 (2022).

Lin, D. et al. Gridization-driven mesoscale self-assembly of conjugated nanopolymers into luminescence-anisotropic photonic crystals. Adv. Mater. 34, 2109399 (2022).

Zhao, D. et al. A dynamic gel with reversible and tunable topological networks and performances. Matter 2, 390–403 (2020).

Zhao, D. et al. A stiffness-switchable, biomimetic smart material enabled by supramolecular reconfiguration. Adv. Mater. 34, 2107857 (2022).

Zhuo, S., Song, C., Rong, Q., Zhao, T. & Liu, M. Shape and stiffness memory ionogels with programmable pressure-resistance response. Nat. Commun. 13, 1743 (2022).

Obst, M. et al. Chemical vapor deposition of ionic liquids for the fabrication of ionogel films and patterns. Angew. Chem. Int. Ed. 60, 25668–25673 (2021).

Liu, X. et al. Aligned ionogel electrolytes for high-temperature supercapacitors. Adv. Sci. 6, 1801337 (2019).

Zhang, C. et al. 3D printed, solid-state conductive ionoelastomer as a generic building block for tactile applications. Adv. Mater. 34, 2105996 (2022).

Lee, H. et al. Shape persistent, highly conductive ionogels from ionic liquids reinforced with cellulose nanocrystal network. Adv. Funct. Mater. 31, 2103083 (2021).

Chen, C. et al. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 5, 642–666 (2020).

Wang, G. et al. Developing cellulosic functional materials from multi-scale strategy and applications in flexible bioelectronic devices. Carbohydr. Polym. 283, 119160 (2022).

Zhu, Y. et al. A non‐Newtonian fluidic cellulose‐modified glass microfiber separator for flexible lithium‐ion batteries. EcoMat 3, e12126 (2021).

Bai, L. et al. Biopolymer nanofibers for nanogenerator development. Research 2021, 1843061 (2021).

Guan, Q.-F., Ling, Z.-C., Han, Z.-M., Yang, H.-B. & Yu, S.-H. Ultra-strong, ultra-tough, transparent, and sustainable nanocomposite films for plastic substitute. Matter 3, 1308–1317 (2020).

Li, G.-L. et al. Constructing π‑stacked supramolecular cage based hierarchical self-assemblies via π···π stacking and hydrogen bonding. J. Am. Chem. Soc. 143, 10920–10929 (2021).

Ke, H. et al. Shear-induced assembly of a transient yet highly stretchable hydrogel based on pseudopolyrotaxanes. Nat. Chem. 11, 470–477 (2019).

Chen, Q. et al. Sustainable, superfast deconstruction of natural cellulosic aggregates toward intrinsically green, multifunctional gel. Chem. Eng. J. 435, 134856 (2022).

Ding, Y. et al. Preparation of high‐performance ionogels with excellent transparency, good mechanical strength, and high conductivity. Adv. Mater. 29, 1704253 (2017).

Liu, K. et al. Flexible and robust bacterial cellulose‐based ionogels with high thermoelectric properties for low‐grade heat harvesting. Adv. Funct. Mater. 32, 2107105 (2021).

Ye, Y. H. et al. Ultrastretchable ionogel with extreme environmental resilience through controlled hydration interactions. Adv. Funct. Mater. 2209787 (2022).

Jung, D. et al. Highly conductive and elastic nanomembrane for skin electronics. Science 373, 1022–1026 (2021).

Kobayashi, Y., Tokishita, S. & Yamamoto, H. Determination of Hansen solubility parameters of ionic liquids by using Walden plots. Ind. Eng. Chem. Res. 59, 14217–14223 (2020).

Nakamura, D. & Nakano, H. Liquid-phase exfoliation of germanane based on Hansen solubility parameters. Chem. Mater. 30, 5333–5338 (2018).

Wang, X., Zhou, J., Pang, B. & Zhao, D. Rapid microwave-assisted ionothermal dissolution of cellulose and its regeneration properties. J. Renew. Mater. 7, 1363–1380 (2019).

Martínez, L., Andrade, R., Birgin, E. G. & Martínez, J. M. PACKMOL: a package for building initial configurations for molecular dynamics simulations. J. Comput. Chem. 30, 2157–2164 (2009).

Thompson, A. P. et al. LAMMPS—a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 271, 10817 (2022).

Humphrey, W., Dalke, A. & Schulten, K. VMD—visual molecular dynamics. J. Mol. Graph. 14, 33–38 (1996).

Acknowledgements

H.Y. and D.Z. acknowledge support by the National Science Fund for Distinguished Young Scholars of China (grant number 31925028) and the National Natural Science Foundation of China (grant number 32171720). G.Y. acknowledges support from the Welch Foundation F-1861, a Norman Hackerman Award in Chemical Research and a Camille Dreyfus Teacher-Scholar Award.

Author information

Authors and Affiliations

Contributions

G.Y., H.Y. and D.Z. supervised the project and designed the experiments. Y.Z. carried out most of the experiments. K.C., S.Z., G.J., W.C., W.B. and X.W. participated in the experiments. G.J. contributed to the analysis of MD simulations. Y.G., Y.L. and W.C. contributed to analysis of the Hansen solubility parameters. Y.Z., D.Z. and H.Y. contributed to the application of e-skin. Y.Z, Y.G., D.Z., H.Y. and G.Y. collectively wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Synthesis thanks Jian Hu, Ho Seok Park and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editor: Peter Seavill, in collaboration with the Nature Synthesis team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1 and 2, Figs. 1–20 and Tables 1–5.

Supplementary Video 1

Solvent-induced exfoliation of P-membrane within 1 s.

Supplementary Video 2

A glass-rod-assisted transfer method to obtain a flat P-membrane.

Supplementary Video 3

Layer-by-layer peeling of the P-membranes.

Supplementary Video 4

Fabrication of a large-area P-membrane.

Supplementary Video 5

Inkjet printing the P-membrane-based flexible circuit chip.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, Y., Guo, Y., Cao, K. et al. A general strategy for synthesizing biomacromolecular ionogel membranes via solvent-induced self-assembly. Nat. Synth 2, 864–872 (2023). https://doi.org/10.1038/s44160-023-00315-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44160-023-00315-5